Commitments

Our Commitments to ESG

Nagambie Resources is aware that its success, both now and in the future, is directly linked to its ability to operate within the community’s expectations on environmental, social and governance (ESG) performance.

As such, NRL is committed to embedding ESG in company values, commitments, systems and culture. We will continually develop, expand and improve our ESG goals and our efforts to achievements commitments as the company develops and grows. The exploration and mining industries play a vital role in achieving sustainability, both by providing the materials needed for a low-carbon transition (such as the critical mineral antimony) and by adopting practices that minimize their environmental and social impacts. There will be challenges and trade-offs involved in balancing the economic, environmental and social dimensions of sustainability and Nagambie Resources is committed to meeting these challenges in an inclusive and transparent way.

By embracing sustainability the company will benefit from reduced costs, increased efficiency, improved shareholder loyalty, enhanced innovation and a positive impact on society and the planet.

Some ESG initiatives Nagambie Resources is building into its operations are as follows:

Ethical standards

Industry leading reporting of exploration results

Nagambie is committed to reporting its exploration results in a responsible and ethical way. As such, the Company strives to report exploration results to the highest standard of the JORC Code 2012. The JORC Code is the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves 2012 edition.

Nagambie’s has developed an industry leading approach to reporting that is particularly relevant when it comes to reporting of results of orientated diamond drillhole intercepts of steeply dipping and narrow mineralised vein systems, such as the vein systems discovered at its Antimony-Gold Project at the 100% owned Nagambie Mine. Nagambie consistently reports estimated horizontal thickness (EHT) of intercepts of near-vertical mineralised vein intercepts. This is because downhole intercept lengths are particularly exaggerated when the drillhole angle is steep and the dip of the intercepted mineralised vein is near-vertical. Simply reporting a downhole length of an intercept does not allow shareholders, or potential investors and their advisors to determine whether the intercept of the mineralised vein is likely to be economical to mine.

Furthermore, because the grade of mineralisation within a vein system will vary along its length, the reporting of the average grade from numerous intercepts of a vein system is also very important for shareholders and potential investors. A length (EHT) weighted average grade is a proxy for the grade of the vein system overall which allows the determination of whether it will be economical to mine all parts of the vein system.

Nagambie believes that reporting EHTs and weight average grades of mineralised vein systems is meaningful and responsible. Without meaningful and responsible reporting of exploration results, in exploration industry risks the flow of capital needed to ensure the world has the minerals it needs.

More details of our approach to reporting exploration results can be found in the ASX announcements about exploration results and by clicking here.

Innovation

Biological extraction of residual gold in the heap leach pile

Total recorded gold production from the Nagambie Mine cyanide heap between 1989 and 1997 was 134,000 ounces and Nagambie Resources considers that a significant amount of gold remains in the heap. Extracting this gold in a toll treatment plant or by additional cyanide heap leaching is currently not viable or economic.

With the financial assistance of the Federal Government’s Innovation Connections Program, Nagambie Resources, together with its joint venture partner Golden Camel Mining, is working with CSIRO to develop a biological method of extracting residual gold from the original heap leach pile at the 100% owned Nagambie Mine.

Bioleaching of gold from tailings is a process that uses microorganisms to extract gold that conventional methods of treatment fail to liberate, at lower environmental impact than the use of conventional lixiviants (for example cyanidation).

Bioleaching involves inoculating the tailings with a suitable culture of bacteria, and providing them with suitable nutrients to thrive. Certain microorganisms can promote gold solubilisation by the excretion of Ligands such as iodide–iodine, which oxidise and forms complexes with gold under mild conditions. The leachate of gold complexes can be collected for gold recovery by various traditional methods. The advantages of this method include low cost, environmental friendliness, and high efficiency. However, there are also some challenges, such as the optimization of process parameters, the recovery of gold and iodine.

The work undertaken by the CSIRO is in its second phase. In the first phase, native and proprietary microorganisms bacterias that could liberate gold from samples of the heap leach material by iodine oxidation were identified. The second and current phase involves carrying out laboratory-scale test work to evaluate the use of these iodide oxidising microorganisms to bioleach gold from gold heap leach tailings in aerated and unaerated columns that simulate heap leach systems.

If the second phase is successful, the next step is to simulate the bioleaching process in the field on a small scale.

The longer-term aim is to develop a technology that can be used to recover gold from tailings stored in geotubes and other third-party tails. The intention is that Nagambie and Golden Camel Mining will have exclusive rights to the technology enabling it to be applied on a commercial basis at the Nagambie Mine and other mine sites.

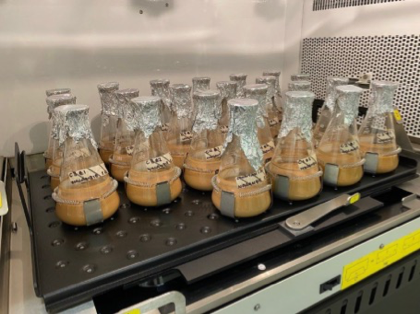

Shake flasks used for bioleaching experiment.

Community

Contributing to the community where we can

The Nagambie Mine has had a long history of contributing to the Nagambie Region. In 1989, full operation of the Nagambie Mine commenced. Mining operations continued until 1993, whilst gold processing operations continued until 1996.

In 1991, a report into the regional effects of the Nagambie Mine was prepared by the then Victoria Department of Manufacturing and Industry Development. The purpose of the report was to provide a preliminary examination of the range of effects that the development and operation of the Nagambie Mine was having on the immediate and surround region.

The report concluded that, at that time, the Nagambie Mine had directly and indirectly contributed to:

- The creation of 82 new jobs at the mine;

- The creation of 21 new short to medium term jobs for the infrastructure improvement projects required by the mine, such as the upgrading of the electricity relay station from Nagambie to Seymour, the pumping of water from the deep lead for production purposes which had a positive preventative outcome for salinity in the region, and the upgrade and sealing of Zanelli Road.

- The creation of a further 73 jobs within Victoria

- The establishment of a new commercial mushroom farming enterprise on Zanelli Road, which was attracted to the area because of the upgrade to Zanelli Road;

- Significant population growth, estimated to be around 4.5%, reversing the trend of population decline that was occurring at the time; and

- The significant stimulation pf the Nagambie Region’s residential land and housing market with dramatic increases in the number of blocks sold, dwelling built and value of building work.

Overall, the report stated that ‘the Nagambie Gold Mine has been, and is, highly beneficial to the economies of the Nagambie and Goulburn Shire Regions’.

In more recent times, Nagambie Resources has made important contributions to the development of the Nagambie town. For instance, Nagambie donated over $15,000 worth of gravel for the landscaping of the ‘Wine Glass Roundabout’ located at the intersections of Odwyer Road and Mitchellstown Road. We are also a proud member of Go Nagambie.

In a case of history repeating itself, the current development of a toll treatment plant at the Nagambie Mine is triggering a further upgrade to the power infrastructure between Nagambie and Seymour. This again will have a positive impact for Nagambie’s residents as it will increase the reliability of the power supply to the township.